Engineering Services Scope

KOMAC provides total engineering services for any and all design, supervision, and technical consultancy projects.

Engineering Services Scope

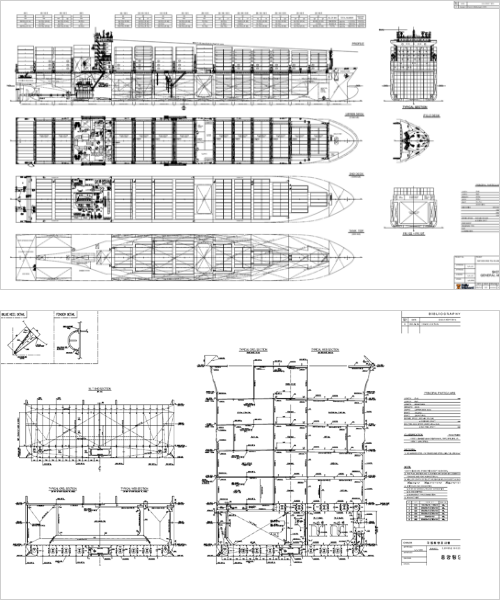

Concept / Contract Design Engineering Services Overview

We thoroughly comprehend, analyze, and aim to accommodate our clients’ specific needs in order to derive the optimal specifications for each vessel’s key components, such as loading capacity, desired speed, propulsion method, hull fidelity, and ultimately provide a meticulous diagnostic of the technical and economical feasibility of such elements, fully compliant with all the latest requirements from Rules and Regulations.

- Implement concept gestation and proposal for the optimal vessel which ultimately satisfies each client’s unique needs

- Compile technical documents regarding basic planning, bidding, contractual specifications, placement, budget estimates, and etc.

- Draft general layout, material estimation and other fundamental design documents

- Provide on-going technical support and consultation in line with ever changing Rules and Regulations

- Administer need-basis support per client specific requirements, such as liaising with proprietors

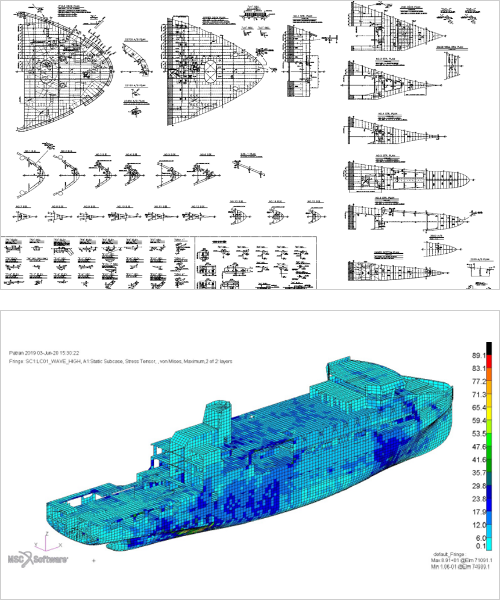

Basic / Detail Design Engineering Services Overview

KOMAC’s highly experienced team of basic design engineers have accumulated vast experience and knowledge through their involvement in the design of more than 1,800 variegated vessels. Through thoughtful and consistent collaboration with our in-house production and structural engineering teams, our designers have also garnered a wealth of knowledge in the demands of vessel construction, and are aptly able to provide optimized designs that satisfy production timelines and methods, the latest IMO regulations, various international accords, and environmental regulations.

- Provide R&D of high-performance propulsion systems utilizing Star CCM (CFD Analysis), OptHull, NAPA, and etc.

- Perform structural analysis (global & local) utilizing Patran, Nastran and etc.

- Perform detailed noise and vibration Analysis and model test

- Draft detailed structural plans, general and machinery arrangements, and systematic diagrams per design discipline

- Perform technical review and approval of third party machinery offerings, and draft purchase order specifications

- Submit applications and reports on inclination tests and sea trials

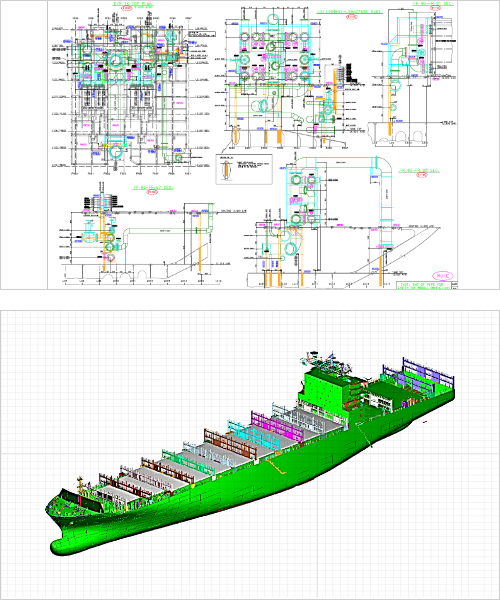

3D Model based Production Design Engineering Services Overview

KOMAC’s production and structural design department utilizes the latest industry standard Aveva Marine (AM) 3D software to create and provide highly accurate production documents for shipyard contractors as well as scrutinizes the potential risk and errors involved in production, thereby contributing to the ultimate efficiency of the construction process.

- Provide excellent manufacturing and installation plans utilizing high-fidelity 3D modeling

- Derive client-specific, highly customized production plan

- Derive material budget and procurement assistance

- Formulate and implement just-in-time recommendations in the case of problems at production site

- Provide consultation regarding peripheral production needs