Think Tank Headquarters

Think Tank Division is a dedicated in-house organization specifically tailored for research and development. It has been designated by the Ministry of Science and ICT as one of Korea’s excellent in-house R&D facilities.

Think Tank Headquarters

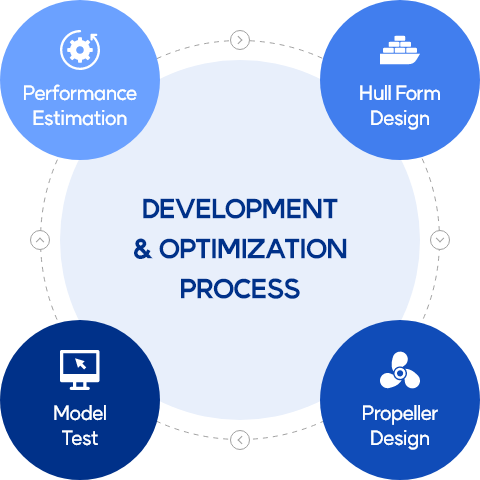

Our in-house Think Tank Headquarters continuously strives to develop optimal hull forms aimed at minimizing fuel consumption through minimization of drag force, thereby meeting the expectations of IMO environmental regulations and curtailing operational costs. We ensure utmost fidelity in such enterprises in hull form development through the organic integration and application of the latest technologies as follows.

Optimal Hull Form Development/Design

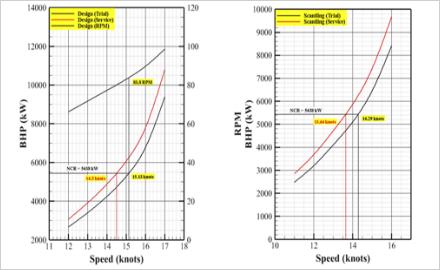

Use NAVCAD and self-developed technology- Performance Estimation based on abundant reference vessels

Hull Form Performance Analysis and Optimization

Use STAR-CCM+- Speed

- Performance (Resistance & Self-Propulsion)

- Cargo Capacity

- Maneuverability

- SeaKeeping

Development/Design of Optimal Propulsion Systems

Performance Evaluation- Resistance Tests

- Self Propulsion Test

- Cavitation Test

- Wake Test

- Paint Test

Performance Evaluation through Scaled Model Trials

Use Self-Developed design know-how- High Efficiency Propeller design

- Cavitation Performance

- Vibration Characteristics

- Cavitation Erosion for rudder

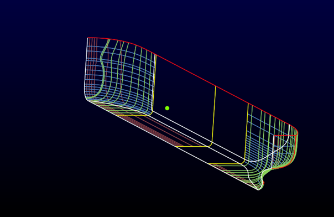

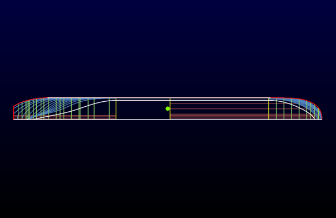

Optimal Hull Form Development / Design

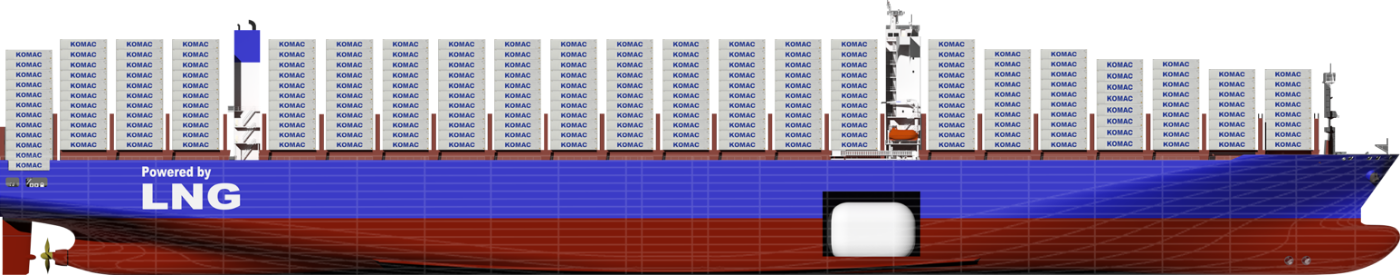

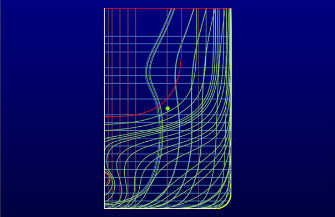

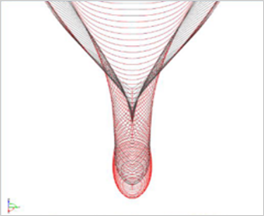

Our Think Tank Headquarters utilizes 3-D Hull design systems that take into consideration hull form production and modification to provide efficient and variegated in-house designs for all types of vessels, ranging from commercial to special purpose vessels. Therefore, we possess a diverse portfolio of hull form case studies as reference for drag force optimization.

Hull Form Production

Hull Form Modification

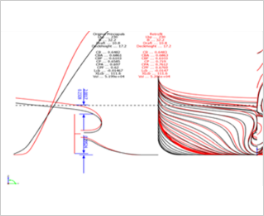

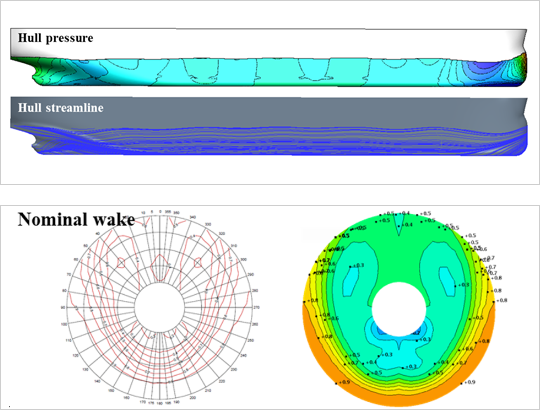

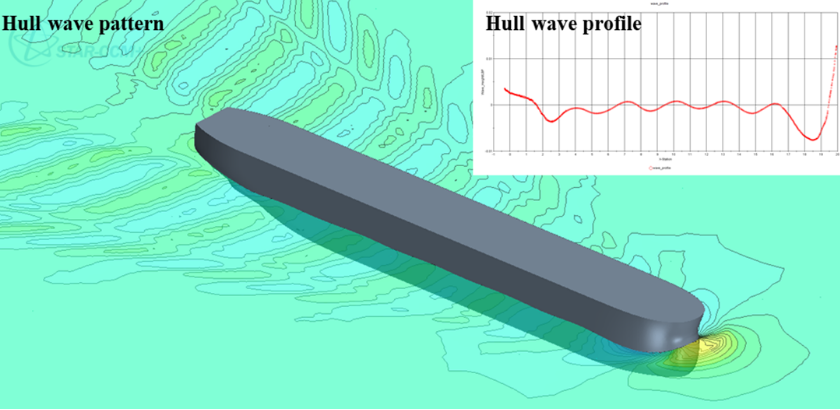

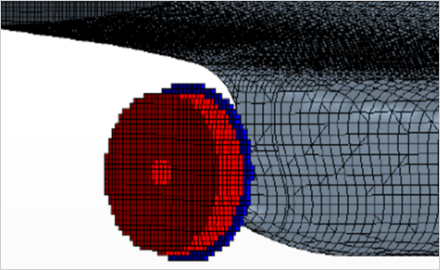

Hull Form Performance Analysis and Optimization

Our Think Tank Headquarters applies CFD data acquired through Star-CCM+ to analyze hull performance in resistance and self-propulsion and implements the ITTC analytical method to predict vessel speed and horsepower. In addition, we study and analyze the flow field and pressure distribution on the surface of the hull, as well as fluid waveform and wake distribution in order to best reflect the improvements to subsequent hull form design and optimization.

Analysis of Resistance Performance

Analysis of Self-Propulsion Performance

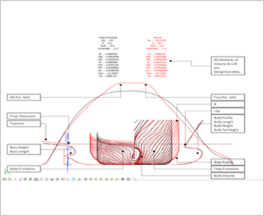

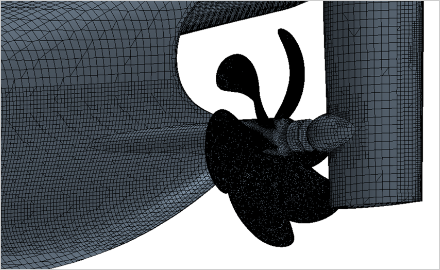

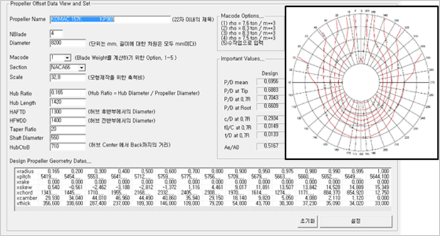

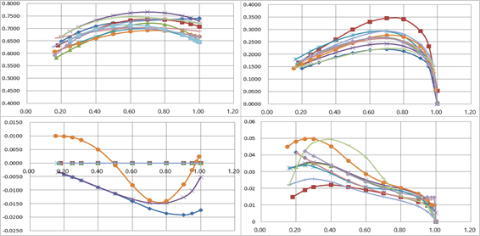

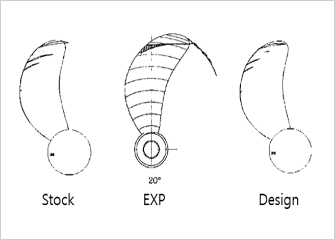

Development/Design of Optimal Propulsion Systems

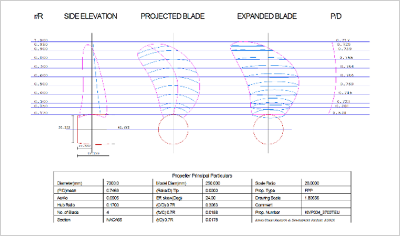

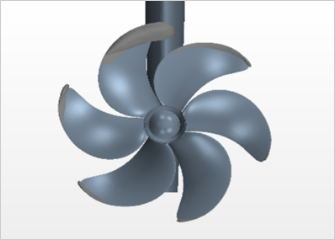

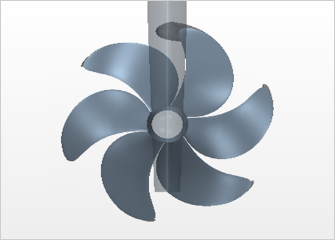

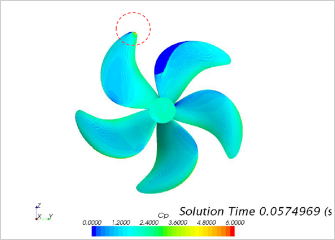

Our Think Tank Headquarters designs Propellers in accordance with the KRISCO Propeller Design Code, and implements STAR-CCM+ to qualitatively evaluate and analyze cavitation effects on designed propellers, conduct research on various forms of cavitation, as well as estimate the risks of propeller erosion through said cavitation in order to best optimize vessel propulsion design.

Propulsion Design & Development

Propeller Cavitation Analysis

Performance Evaluation through Scaled Model Trials

The Think Tank Headquarters implements all tasks relating to the final performance evaluations and scaled model trials of developed hull forms and subsequent propulsion systems as outlined below.

- Review suitability of trial institute (Equipment, Facility, Performance, Personnel, etc.)

- Review trial contract and execution schedule.

- Compile and provide appropriate data for model trial

- Delineate and review Test Scope of Model Trial

- Scrutinize specifications and fidelity of Stock Propellers to be used in Model Trials

- Confirm application of ITTC recommended values during trial (fluid temperature, mass, kinematic viscosity)

- Examine correlation and accuracy between trial values (speed, horsepower, RPM Margin, self-propulsion) and estimates of said values conducted prior to trials.

- Appraise validity of measurement methods and acquired data during wake measurement and hull streamline trials.

- Examine trial result report for proper consideration and implementation of provided vessel specifications and hydrodynamic data.

- Review adequacy of estimated effective vs. delivered horsepower.

- Analyze various resultant values in drag and propulsion.

- Review whether estimates of drag and speed were accurate based on the ITTC 1978 analytical method.

- Determine and present satisfaction of contract-specified speed.